How Iron-based Nanocrystal Ring Iron Cores Enhance Common Mode Inductance Performance

In modern power electronics and communication systems, electromagnetic interference (EMI) has become one of the most critical challenges engineers must address. From switch-mode power supplies and inverters to EV chargers and industrial control equipment, controlling noise is essential for safety, reliability, and regulatory compliance. At the heart of many EMI filtering solutions lies the common mode inductor, and its performance is largely determined by the magnetic core material.

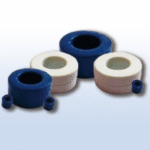

Among available options, the Iron-based Nanocrystal Ring Iron Core for Common Mode Inductance has emerged as a highly effective solution, offering excellent magnetic properties, compact size, and stable performance across a wide frequency range.

Why Core Material Matters in Common Mode Inductors

A common mode inductor works by suppressing noise currents that flow in the same direction along multiple conductors. To achieve effective noise attenuation, the magnetic core must provide:

High permeability for strong inductance

Low core loss at high frequencies

Stable magnetic behavior under varying temperatures

High saturation resistance to prevent performance degradation

Traditional ferrite cores may struggle to meet all these requirements simultaneously, especially in high-power or wide-frequency applications. This is where iron-based nanocrystalline materials provide a clear advantage.

What Is an Iron-based Nanocrystal Ring Iron Core?

Iron-based nanocrystal cores are manufactured using rapidly quenched alloy ribbons followed by precise annealing. This process forms an ultra-fine grain structure, typically in the range of 10–20 nanometers, giving the material exceptional magnetic characteristics.

Key features include:

Very high magnetic permeability

Low coercivity and low hysteresis loss

Excellent high-frequency performance

High saturation magnetic flux density

Good thermal stability

When formed into a ring (toroidal) shape, these benefits are further enhanced, making nanocrystal ring cores especially suitable for common mode inductance applications.

How Nanocrystal Ring Cores Improve EMI Suppression

High Inductance in Compact Designs

Thanks to their high permeability, iron-based nanocrystal ring cores achieve higher inductance values with fewer turns. This allows engineers to design compact common mode inductors without sacrificing noise suppression performance.

Wide-Band Noise Attenuation

Nanocrystal common mode choke cores are effective across a broad frequency spectrum, making them ideal for systems where both low-frequency and high-frequency interference must be controlled.

Reduced Core Loss

Lower core loss means less heat generation during operation. This improves efficiency and extends the service life of the inductor, particularly in continuous-duty applications.

Strong Anti-Saturation Capability

Iron-based nanocrystal materials maintain stable performance even under high current conditions, reducing the risk of inductance collapse during current surges.

Advantages of Ring-shaped Structure in Common Mode Inductance

The toroidal geometry of a ring iron core provides several practical and magnetic benefits:

Closed magnetic path minimizes flux leakage

Uniform magnetic field distribution improves inductance consistency

Lower electromagnetic radiation reduces secondary interference

High mechanical strength supports reliable winding and assembly

These features help common mode inductors deliver consistent EMI suppression in demanding environments.

Typical Applications of Nanocrystal Common Mode Inductor Cores

Iron-based nanocrystal ring iron cores are widely used in:

Switching power supplies

Solar inverters and energy storage systems

EV charging stations

Industrial automation equipment

Communication power systems

Medical and precision electronic devices

In each of these applications, stable EMI suppression and long-term reliability are critical requirements.

Why Choose Hall Magnetics for Nanocrystal Ring Cores

While nanocrystalline materials offer inherent advantages, the actual performance of a common mode inductor heavily depends on core quality and manufacturing precision. Hall Magnetics specializes in producing high-performance iron-based nanocrystal ring iron cores with strict control over material composition, annealing processes, and dimensional tolerances.

Hall Magnetics provides:

- High-permeability nanocrystal common mode choke cores

- Low-loss cores optimized for EMI filtering

- Custom sizes, coatings, and magnetic specifications

- Consistent quality for mass production

- Technical support for application-specific designs

These capabilities make Hall Magnetics a reliable partner for manufacturers seeking stable, high-efficiency EMI suppression solutions.

Conclusion

The Iron-based Nanocrystal Ring Iron Core for Common Mode Inductance represents a powerful advancement in EMI filtering technology. By combining high permeability, low loss, strong anti-saturation capability, and a compact ring-shaped design, these cores significantly enhance the performance and reliability of common mode inductors.

As electronic systems continue to operate at higher frequencies and power levels, selecting the right core material becomes increasingly important. With proven expertise and advanced manufacturing capabilities, Hall Magnetics delivers nanocrystal ring core solutions that meet the evolving demands of modern power and electronic systems.