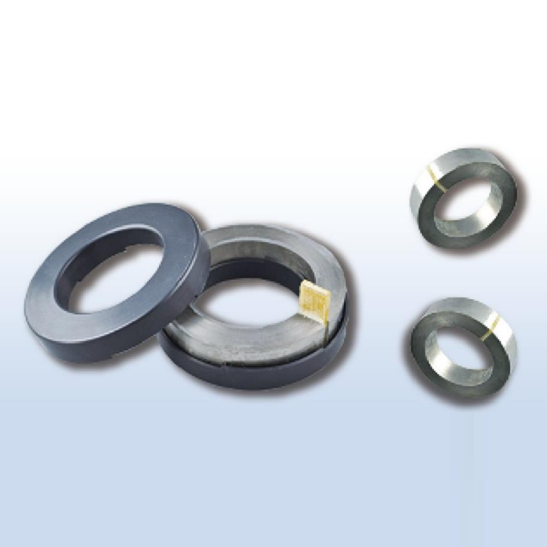

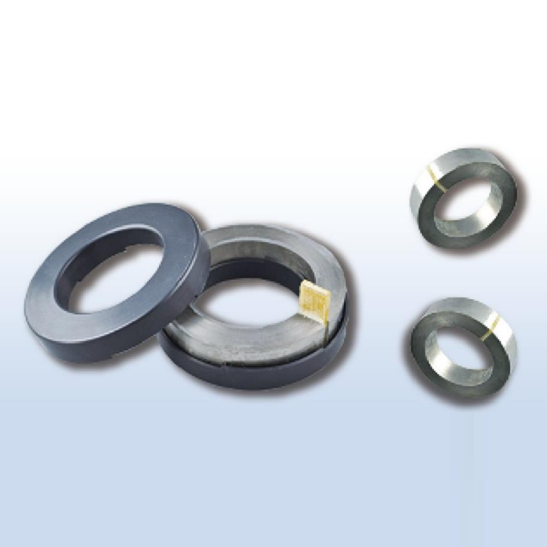

Annular Notch Amorphous Inductor Core: Performance, Efficiency, and Innovative Design Applications

High efficiency, low energy losses, and small-size components are more urgent in modern power electronics and renewable energy systems. Engineers and manufacturers have been searching for magnetic materials that can provide stable inductance, low hysteresis loss, and reliable frequency response.

Among these innovations, the annular notch amorphous inductor core has become a revolutionary component in advanced inductor and transformer design. The unique properties of its amorphous alloy material, further enhanced by the annular notch geometry, create superior magnetic properties and efficiency. This article will explore how its materials science, design optimization, and applications can help modern industry achieve stable and energy-efficient operation.

The Scientific Principles of the Annular Notch Design

An annular notch means a specially designed gap in a ring-shaped magnetic core. This design allows for precise control of magnetic flux and prevents flux congestion in certain areas of the core.

This notch will serve as a means for the engineers to control the magnetic circuit, thereby achieving:

Improve inductor linearity at various current levels

Reduce magnetic flux leakage in high-frequency circuits

Reduce core saturation under transient load conditions

This structure makes for very stable performance under loads that may have a variation in frequency or voltage-a major advantage in applications such as power inverters, battery management systems, and electric vehicle converters. The ring-shaped notch structure helps to suppress noise and electromagnetic interference, improving the reliability of surrounding components.

Material Advantages of Amorphous Alloys

Unlike traditional crystalline materials such as silicon steel, amorphous alloys have a disordered atomic structure. This disordered arrangement drastically reduces resistance to magnetic domain movement, hence reducing hysteresis losses and minimizing eddy current losses during operation.

The main advantages of amorphous materials include:

Extremely low core loss, especially at high-frequency operating conditions

High permeability, hence increasing magnetic response

Stable magnetic properties even under temperature variations

Lightweight and corrosion-resistant, making them ideal for compact electronic designs

Besides, the high resistivity of the amorphous magnetic cores makes them appropriate for power conversion systems where minimizing heat buildup is crucial. This results in longer lifespan, higher power density, and better energy efficiency, meeting modern environmental and energy efficiency standards.

Precision Manufacturing and Process Innovation

The performance of amorphous inductor cores largely depends on the precision of their manufacturing process. Hall Magnetics follows a multi-step production system to ensure consistent product quality and optimal magnetic performance.

The process includes:

High-pressure strip forming to ensure consistent geometry and density

Vacuum annealing in order to restore the amorphous structure and magnetic orientation.

Protective surface coating to ensure oxidation resistance and durability

Automated quality inspection to guarantee consistency across all batches

These processes ensure that every annular notch amorphous inductor core produced by Hall Magnetics maintains global standards regarding dimensions, stability of permeability, and mechanical strength, maintaining reliability even in harsh environments such as industrial automation and smart energy systems.

Expanding Applications in Modern Industry

Offering a wide range of possible uses, the annular notch amorphous inductor cores are part of many advanced technologies:

Photovoltaic inverters: Improve DC-to-AC conversion efficiency and reduce switching losses.

Electric vehicle powertrain systems: Provide compact, lightweight magnetic components with excellent thermal stability.

5G base stations and communication equipment: Ensure signal stability with reduced high-frequency noise.

Smart energy storage systems ensure smooth power flow and improve energy distribution.

Industrial power supplies: Provide stable inductance in harsh or high-temperature environments.

Amorphous silicon magnetic cores maintain performance stability under pressure, making them ideal for emerging smart technologies and sustainable energy systems.

Optimizing Performance Through Design Engineering

For engineers, the annular notch amorphous inductor core provides a flexible basis for design optimization. It provides great accuracy in the control of inductance and efficiency by fine-tuning parameters such as the air gap position, core thickness, and winding configuration.

Designers can achieve the following:

Improving heat dissipation through balanced winding layout

Reducing magnetic losses through optimized slot geometry

Achieving high-frequency stability by adjusting the interaction between the windings and the magnetic field

Hall Magnetics provides custom engineering support to help customers develop the right core size, inductance value, and structural configuration for their applications to ensure performance and cost-effectiveness. We have years of export experience to serve you.

Conclusion

The annular notch amorphous inductor core represents a new generation of high-performance magnetic components, embodying materials science, precision in design, and energy efficiency. Its structural innovation and magnetic reliability make it a crucial component of future power systems, contributing to the global transition to cleaner, smarter energy.

Hall Magnetics is committed to providing customers with advanced amorphous magnetic core solutions to achieve superior performance, lifespan, and reliability. Whether applied in renewable energy, automotive electronics, or industrial control, our cores ensure systems operate with maximum efficiency and stability. We look forward to cooperating with you.