How Annular Notch Amorphous Inductor Core Improves Energy Efficiency

Energy efficiency is no longer a trend; it’s a necessity for modern electronics. Companies require electronics that use less power, generate less heat, and are longer lasting. The annular notch amorphous inductor core is one of the quite insignificant but very significant components. This new-age core is in widespread application in switching power supplies, inverters, electric cars, and renewable energy systems. Its specialized materials and design significantly reduce energy waste and enhance system performance.

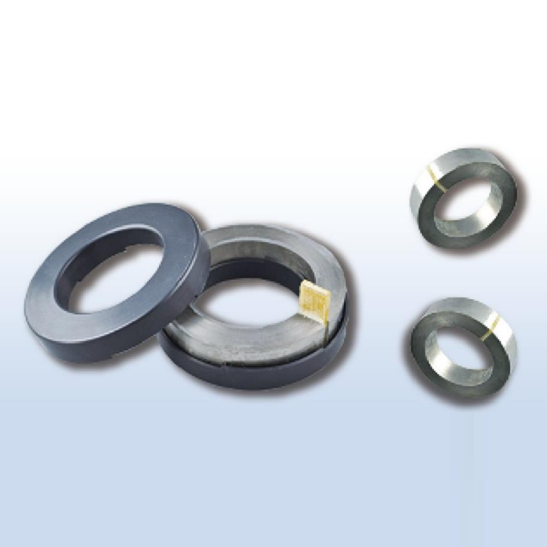

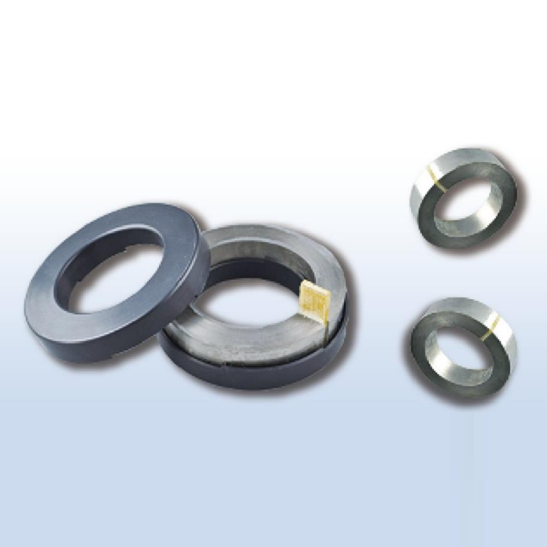

What is an Annular Notch Amorphous Inductor Core?

Unlike traditional silicon steel cores, it consists of an amorphous alloy. Amorphous metals lack a regular atomic arrangement, resulting in low losses, high permeability, and high efficiency.

The annular notch design improves the flow of magnetic flux within the core, effectively reducing eddy current losses. This means less wasted energy and uniform performance even under high-frequency applications.

How it saves energy

Lower losses

Traditional iron cores convert energy into heat and waste it, while amorphous cores dissipate less energy, which means there is cooler operation of the system and greater energy efficiency.

High magnetic permeability

High magnetic permeability means the inductor can function at lower currents, thus reducing power requirements and energy consumption.

Low heat generation and long lifespan

Low losses mean less heat generation, lower system temperatures, increased lifespan, and reduced maintenance costs.

Small size, high energy

The high efficiency of the amorphous core allows high power operation in compact space, contributing to device miniaturization and material savings.

Wide frequency adaptability

The annular notch gap design offers stable operation over a wide frequency range, and thus it is highly suitable for high-frequency applications like DC-DC converters and photovoltaic inverters.

Practical Applications

Switching power supplies: Improve energy efficiency in laptops, servers, and consumer electronics.

Solar and wind power systems: Increase efficiency in renewable energy conversion.

Electric vehicles: Optimize charging systems and converters, improve battery performance, and increase range.

Smart Grid: Used for power regulation and monitoring, helping the grid operate more efficiently.

Industrial Equipment: Reduces energy loss and improves stability in large motors, drive systems, and automation equipment.

Through its diverse applications, this advanced magnetic core helps various industries achieve energy savings while maintaining stable performance.

Why Manufacturers Choose It

Manufacturers favor this core because it combines high efficiency, cost savings, and compliance with international energy efficiency standards. With advancing energy-saving laws, annular notch amorphous inductor cores ensure products easily adapt to such standards without a compensating increase in cost.

Compared to traditional magnetic core materials, amorphous cores are more environmentally friendly. They facilitate the global transition toward sustainable development and carbon emissions reduction for high-volume production. This not only benefits end users financially by saving them money on lower electricity costs but also allows companies to create a cleaner brand image. For the majority of manufacturers, adopting this technology is not only a technological advancement but also a marketing advantage.

At Hall Magnetics, we specialize in producing high-quality amorphous and nanocrystalline magnetic cores, including annular notch amorphous inductor cores. Through modern production facilities and rigorous quality control, we provide customers with products of international levels that are consistent and stable. Our experts also offer customized solutions based on customer specifications, which help in increasing energy efficiency and reducing the cost factor.

Simple Maintenance Tips

Keep the core clean and free of dust.

Keep checking the windings regularly for loose contacts.

Offer secure fixing to avoid vibration.

Precision systems require regular testing and calibration.

These small steps will ensure longer-lasting and more stable core performance.

Conclusion

Annular notch amorphous inductor cores are not just magnetic components; they are a key solution to modern energy conservation. They allow devices to reduce losses, reduce heat, and improve reliability. These high-performance cores form the core of applications ranging from consumer electronics to new energy and industrial equipment.

At Hall Magnetics, we are committed to providing innovative magnetic core solutions that enable our customers to achieve high performance and sustainable growth. If you are looking to reduce energy consumption, save costs, and improve efficiency, our product and technical teams will provide you with the most suitable support.